Most consumer electronics are guaranteed within warranty and the appliances like air conditioners and washing machines usually function for more than a decade, and we seldom replace them with a brand-new one right after the warranty.

However, if we acknowledge the sense of maintenance and have a technician check the unit on a regular basis, it not only assures the functionalities from a professional perspective but is also more economical. Just as most consumer electronics, when warranty expiration comes to the life-saving machines that take the role in the critical moment, it is neither necessary to cast them away upon expiration. Instead, the expired AED may stay in operation undoubtedly.

What differs AED from appliances is why AEDs are made: Save Lives, so conducting maintenance test and managing are essential. In order to continue AED operation after warranty with assurance and responsibility, it requires a thorough regular maintenance test . The same goes for the AED within warranty, because the various conditions in different environments might have impacts on the components of AED, which lead to unexpected malfunctions. On top of that, these test data must rely on smart management to ensure that managers can keep track of the status of each AED device.

Furthermore, in the summary of FDA and IEEE Recall Records, several malfunctions could not be told from merely AED self-test results. A compromised capacitance is one of the common reasons, which might cause the inability to start charging, charging for a long time, low energy shock by insufficient charging, etc. Technically speaking, an AED self-test is not enough to verify its availability, because the self-test only activates the circuit to check up on the status of its MCU and firmware, instead of actually going through the entire process of charging and discharging. Therefore, no matter how long after the AED was purchased, no one ever has the quantified records of defibrillation-related data such as remaining battery level, shock energy, and shock waveform to trace with. And those indeed are essential to our regular evaluation of the AED defibrillation performance.

A Total Solution Keeps AED in Operation and Provides Peace of Mind

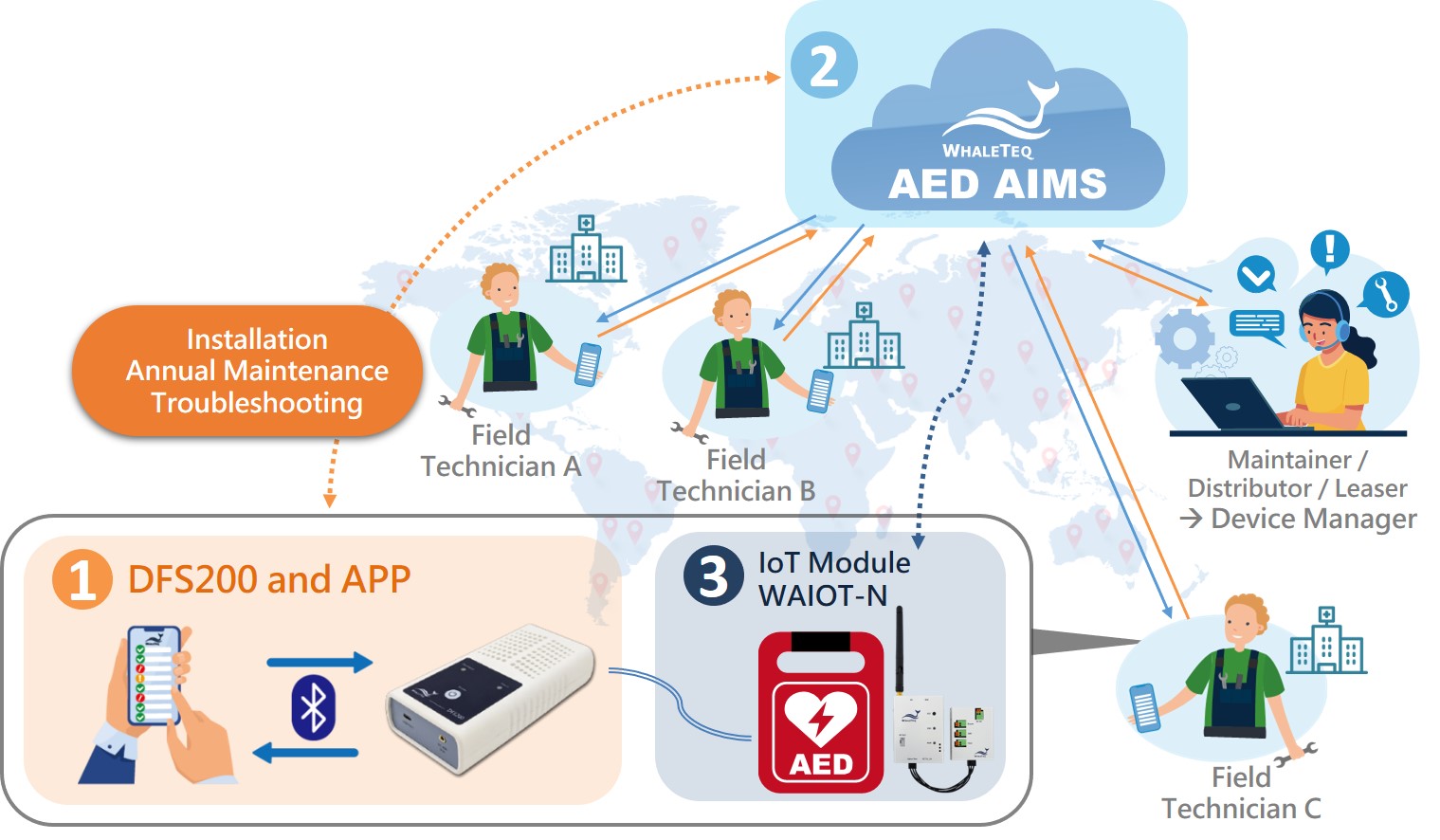

WhaleTeq Co., Ltd developed a systematic AED after-sales maintenance total solution, making use of an smart management system, which properly records and utilize AED equipment information and inspection data. This AED after-sales maintenance system includes: regular maintenance test, overall inspection services offered by field inspector, and using the AIMS to manage test data.

AED Regular Maintenance Test to Make Up for the Lack of Verifying Defibrillation Performance in Self-test

A.Discharge Test (Shock Energy Test)

/%E6%94%BE%E9%9B%BB%E6%B8%AC%E8%A9%A6.jpg)

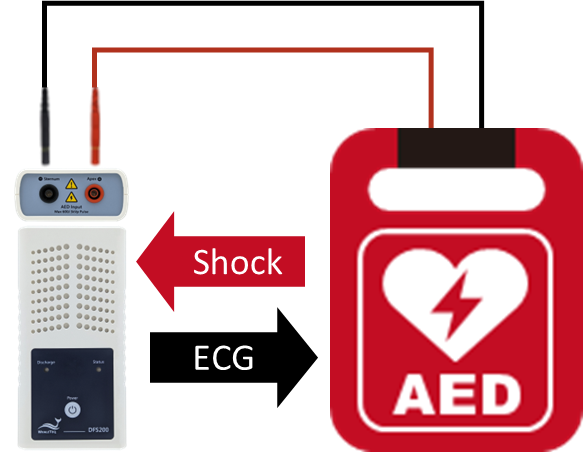

The DFS200 Field Tester and AED under Test Wiring Schematic

Note:

- In any progress, the AED will not be disassembled. Neither damage will be made.

- In the Discharge Test, it is recommended to replace the original battery with the test battery temporarily, in order to keep the original battery intact and return it to operation if qualified in Battery Test.

- As the schematic above, connect AED cables to the DFS200, as if the DFS200 is a patient in need of resuscitation and being attached with patches from AED.

- On the DFS200 Mobile APP, set Pass Range to tell if the AED is qualified in defibrillation performance, according to the manufacturer′s requirements.

- Use the DFS200 APP via Bluetooth to have the DFS200 simulate a patient with the ECG signal under test, by playing the ECG signals before and then after shock.

- As if in an emergency, activate the AED, waiting for its analysis on the ECG signals played from the DFS200. If the AED determines to give a shock for resuscitation, it will automatically start charging. Technicians may follow the voice instruction and press the flashing button to discharge to the DFS200.

- The Purpose at this stage: Verify if the AED is capable of determining whether to shock on the ECG under test based on the manufacturer′s requirements.

- After the DFS200 receives the shock, the qualification based on Pass Range, shock energy (joules) and shock waveform appear on the DFS200 APP.

- The Purpose at this stage: Verify if the AED′s output energy and waveform meet the manufacturer′s requirements.

B. Independent Battery Test

/%E9%9B%BB%E6%B1%A0%E6%B8%AC%E8%A9%A6.jpg)

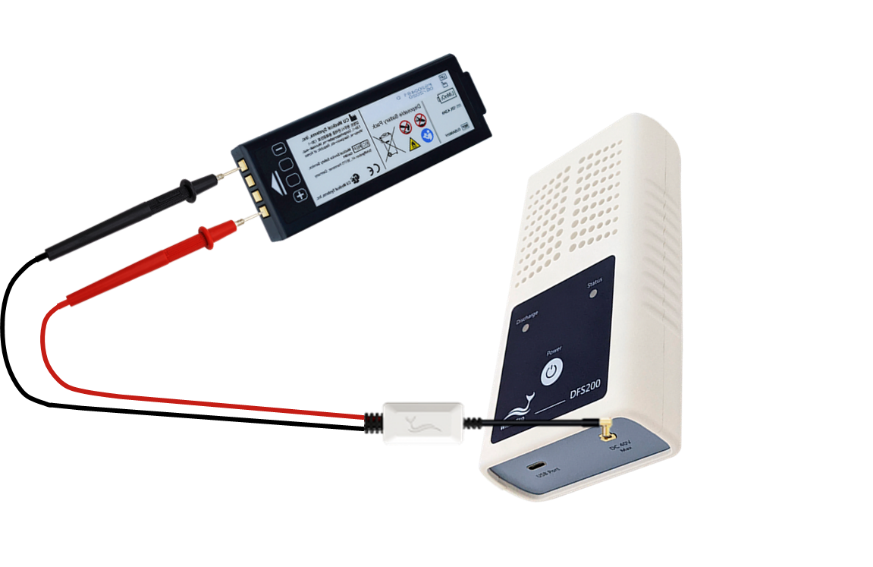

AED Battey under Test and the DFS200 Field Tester Wiring Schematic

- As the schematic above, take the original battery out of AED.

- Use the DFS200 APP via Bluetooth to activate the Voltage Multimeter embedded in the DFS200 and measure the remaining level of the original battery.

- Using a Battery Measurement Probe with Load which simulates the load increment upon AED startup allows technicians to acquire an objective and accurate measurement. For detail, please refer to the Application Note published on WhaleTeq's official website. From which note, you can also find a reference table of the voltage measurement and the remaining battery level of different brands. Technicians may look up the table and decide if the original battery needs to be replaced.

Helping AED Managers Put Scattered Information Together

Meantime, the DFS200 can upload the test data to the WhaleTeq AED CMMS Platform. The system features smart management to keep the latest AED operation status in hand, including after-sales records, auto-alert for abnormal events, statistical analysis, etc.

Moreover, its dispatch management empowers AED distributors, maintainers, and leasers to advance the efficiency of after-sales services.

Plus, with WhaleTeq IoT Module WAIOT-N installed to each AED, the AED CMMS Platform can automatically collect AED self-test results and AED cabinet status, such as door opened and AED taken, which enables device managers to remotely monitor every single AED thoroughly.

/AIMS_EN.png)

Solving AED Managing Problems All at Once

A complete AED After-sales maintenance solution does not rely on AED self-test alone, but include regular maintenance test and smart management. This thorough inspection helps the device managers ensure AED functions properly within warranty and record AED performance test history; even after the warranty, it helps the managers continue AED operation with assurance and responsibility, also sparing valuable resources of medical equipment in the meantime.

On top of those essentials, the systematic management and application of each AED device information and test data can accomplish the remote monitoring over PAD (Public Access Defibrillation), optimize AED after-sales services, and save costs and labor. Eventually, to bring in greater well-being to local communities.